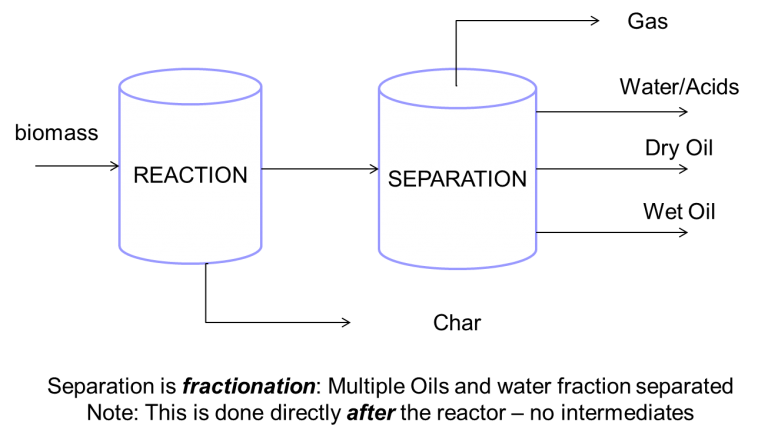

Our 2nd Generation pyrolysis reactor is based on its unique reactor design and patented separation process which distinguishes from previous generation pyrolysis technologies. This innovative separation process produces fractions directly from the feedstock and separates the water and acids fractions from the bio-crude oil produced through the thermochemical process that takes place inside the reactor with temperatures above 900 Celsius. As a result, multiple products simultaneously are extracted from the process.

The technology has several characteristics:

Compact Design

One of the design criteria for this technology was that it should require little ground space and little height. This was needed to be able to build it on mobile platforms.

This mobile plant can locally convert biomass into products with a fast start-up and easy fully automated operation providing the ability to use in multiple locations in a short period of time possible.

© 2020 PYROTECH ENERGY PTY LTD | Terms of Use | Privacy Policy | All Rights Reserved |