2nd generation pyrolysis technology is unique in simultaneous production of several qualities of bio-crude oil. Normally we distinguish these oils between two qualities: Dry Oil (3w% water content) and Wet oil (20w% water content). The Dry oil has an HHV of 24 MJ/kg and the Wet oil has an HHV OF 17 MJ/kg. The Wet oil is liquid at room temperature, whereas the Dry oil is solid in room temperature. Wood waste and agriculture residue are feedstock’s that meet the requirements for thermochemical conversion into bio-crude oil. Biomass itself is carbon-neutral and its use produces much less SOX and NOX due to the much lower content of nitrogen and sulphur in the biomass than in coal or petroleum based oils. Biomass can be converted to liquid fuels via pyrolysis. Pyrolysis can be operated at atmospheric pressure. Hence, the conversion of biomass into a liquid fuel via pyrolysis has attracted great interest.

Bio-crude oil is the primary product of interest, which is an organic mixture of alcohols, ketones, aldehydes, phenols, ethers, esters, sugars, furans, alkenes, nitrogen and oxygen compounds.

The comparison of pyrolysis oil produced from the PyroFlash processs of wood and agriculture waste streams from heavy crude oil.

| Properties | Bio-oil | Heavy fuel oil |

| Moisture content (wt.%) | 15.0–30.0 | 0.1 |

| Ph. | 2.5 | Neutral |

| Specific gravity | 1.20 | 0.94 |

| C (wt.%) | 54–58 | 85 |

| H (wt.%) | 5.5–7.0 | 11.0 |

| O (wt.%) | 35–40 | 1 |

| N (wt.%) | 0.0–0.2 | 0.3 |

| S (wt.%) | trace | 0.5–3.0 |

| N (wt.%) | trace | 0.3 |

| Ash (wt.%) | 0.0-0.2 | 0.1 |

| Higher heating value (MJ/kg) | 17–24 | 40 |

| Viscosity, at 500°C (cP) | 40–100 | 180 |

| Solids (wt.%) | 0.2–1.0 | 1.0 |

| Distillation residue (wt.%) | up to 50 | 1 |

| Pour point (°C) | –33 | –18 |

| NOx emission (g/MJ) | <0.7 | N/A |

| SOx emission (g/MJ) | 0 | N/A |

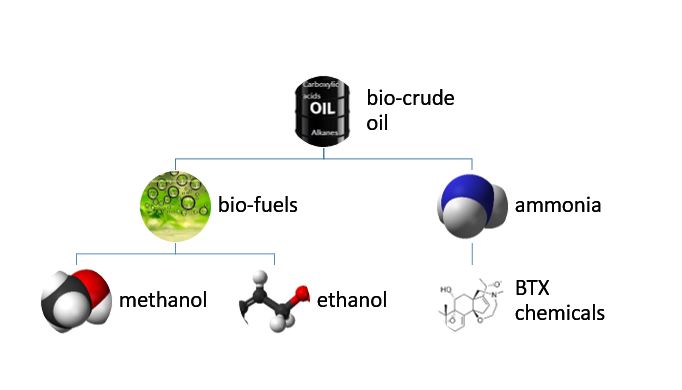

Applications of Bio-crude oil (Pyrolysis oil)

Bio-crude oil derived from woody biomass and agriculture residue is both a precursor for fuel as well as bio-chemicals.

The bio-crude oil can be used:

© 2020 PYROTECH ENERGY PTY LTD | Terms of Use | Privacy Policy | All Rights Reserved |