To produce sustainable hydrogen one has two options. Solar/Wind in combination with electrolysers and the gasification route.

The electrolyser route is resulting in a hydrogen cost price of 8 AUS$/kg H2 (Electricity price of 10c/ KWH) when based on 8000 hours/day operation. However solar/wind is only available for 2000+ hours/year resulting in a cost price of 14 AUS$/kg H2 as below graph shows.

The current price of hydrogen production using natural gas is around 2 AUS$/kg H2 (without CO2 taxation). Electricity price has to drop dramatically and CAPEX as well to have electrolysers become competitive, which is unlikely.

The gasification route has much more potential to match the natural gas based pricing of hydrogen. There are a number of reasons:

By focussing on gasification the Australian government is solving two birds with one stone: valorisation of waste and reducing fossil fuels consumption. Electrolysers only do the latter.

A waste to hydrogen route is a solution that can be applied quickly throughout the country and has enormous export value

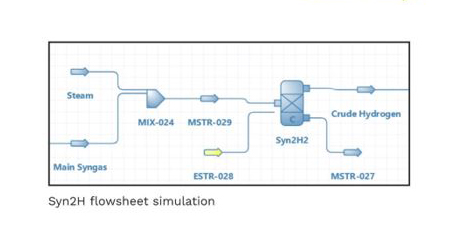

Hydrogen is produced from the syngas of the gasification installations using SYN2H technology. With this route we produce green hydrogen.

The SYN2H technology is aimed at converting syngas into pure hydrogen. The traditional route to convert syngas into hydrogen requires a catalyst for the water- gas shift reaction, CO+H2O>CO2+H2 to boost hydrogen production.

SYN2H technology is unique in its requirements to produce hydrogen as:

Gasifiers equipped with SYN2H extension become serious rivals of the electrolysis route to hydrogen. The combination has a number of advantages over electrolysis.

© 2020 PYROTECH ENERGY PTY LTD | Terms of Use | Privacy Policy | All Rights Reserved |