The main gases produced in the pyrolysis and gasification installations for wood waste and agriculture residue include carbon dioxide, carbon monoxide, hydrogen, methane, ethane, ethylene, propane, sulphur oxides, nitrogen oxides, and ammonia. CO and CO2 are mainly originated from the decomposition and also reforming of carboxyl and carbonyl groups. Light hydrocarbons stemmed from the decomposition of weak methoxy and methylene bonds. Hydrogen is the result of the reforming and decomposition of C–H groups and aromatics.

Reaction temperature has a significant influence on pyrolytic gas yield and composition. As the pyrolysis temperature increases, thermal degradation and devolatilisation of biomass enhances. Simultaneously, the produced volatiles undergo a series of secondary reactions such as decarboxylation, decarbonylation, dehydrogenetaion, deoxygenation and cracking to form pyrolytic gas.

Moisture content is another parameter influencing the pyrolytic gas production. High moisture content can enhance the extraction of water-soluble components from the gaseous phase, hence causing a significant decrease in the yield of pyrolytic gas. Particle size of biomass is another parameter influencing the yield and composition of pyrolytic gas. Smaller particle size of biomass feedstock favours the cracking of the components or the reactive intermediates, producing more H2 and CO while less CO2.

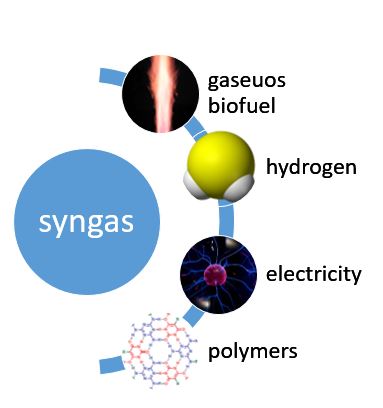

Syngas from the pyrolysis or gasification process is directly available as a product and it’s not used for heating the process as air is used for direct firing inside the reactor thus resulting in high quality syngas ranging its HHV between 5.4 MJ/kg to 6.7 MJ/kg. Using a gas generator, it can be transferred into heat and electricity. Both installations produce enough syngas to support the systems electricity demands. The Syngas produced is rich inn hydrogen and burns with a colourless flame.

© 2020 PYROTECH ENERGY PTY LTD | Terms of Use | Privacy Policy | All Rights Reserved |